Application:

E235 N Steel Tube For Auto Industry And Hydraulic System, Automobile Fuel Line, Oil Tube,

Alloy Or Not:

Non-Alloy

Section Shape:

Round, Round

Special Pipe:

EN Pipe

Outer Diameter:

3.75 - 60 Mm, 3.75 - 60 Mm

Thickness:

0.5 - 6 Mm

Standard:

ASTM, Bs, DIN, GB, JIS, ASTM A179-1990, BS 6323, DIN 1629/3, DIN EN 10216-1-2004, DIN 1630, DIN 2391, DIN 17175, DIN EN 10305, DIN 2448, GB/T 8163-1999, GB/T 8162-1999, GB/T 3639-2000, JIS G3445-2006

Grade:

10#, 20#, 45#, 16mn, ST37, ST52, ST45, ST35.8, St37-2, ST35.4, St52.4, St45-4, ST35, ST37.4, ST54, 10#-45#, 16mn, ST35-ST52

Surface Treatment:

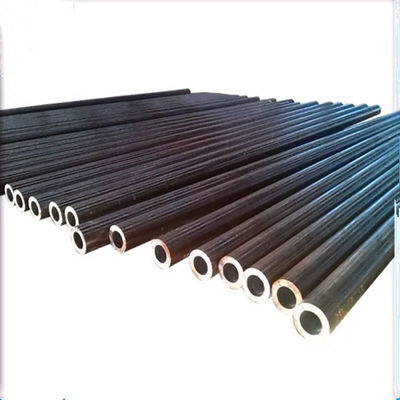

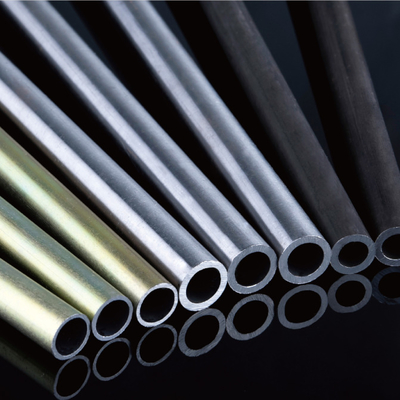

Annealed Galvanized, Or Black Phosphated E235 N Cold Drawn Seamless

Tolerance:

±5%

Processing Service:

Cutting

Name:

E235 N Cold Drawn Seamless Steel Pipe

Standard::

DIN 2391, EN10305-1, EN10305-4, BS 6323, ISO 8535

STEEL GRADE::

ST30Si, ST30Al, ST35, ST37, ST37.4, ST45, ST52, ST52.4, Etc

Delivery Condition::

BK, GBK, BKW, BKS Or NBK For E235 N Cold Drawn Seamless Steel Pipe

Certificate::

ISO 9001 TS16949

Technique:

Cold Drawn, Cold Drawn

Secondary Or Not:

Non-secondary

Certification:

TS16949 ISO9001 For E235 N Cold Drawn Seamless Steel Pipe

Type:

Seamless Steel Pipe

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!